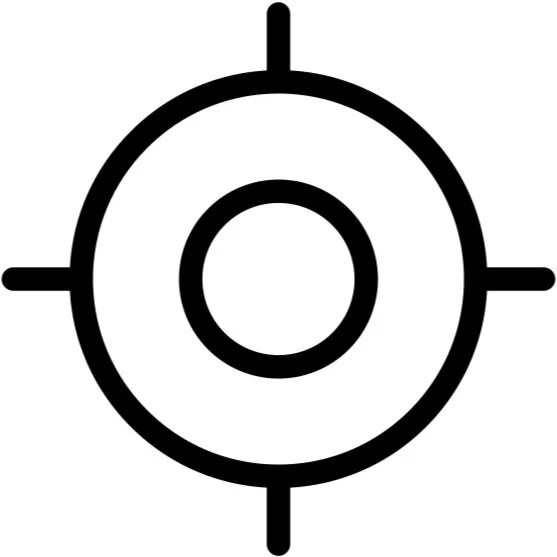

Precious Plastic is a combination of people, machines, platforms and knowledge to create an alternative global recycling system. Precious Plastic exists to reduce plastic waste. Sometimes we do it through boosting recycling, sometimes through new biodegradable materials, some other times by adopting zero waste lifestyles. Whatever works.

Our solutions see people as the key element to fix the plastic mess. Precious Plastic’s approach counts on people to bring about the necessary change. Small steps, multiplied by millions. That's where we can win our battle. We don't believe in techno-utopian, fix-it-all, dream technology.

Goal: Help Precious Plastic upgrade their Version 4 open source plastic recycling machines and systems, while increasing my knowledge of sustainable design and living.

Milwaukee, Wisconsin to Eindhoven, Netherlands

Precious Plastic is a community where people help in many more ways than one. Given the timing of my arrival and the needs at the time, I began by working as a Vegan Chef, cooking lunches and dinner for the team. I was drawn to this role initially because I had been a vegetarian for some time and wanted to make the transition to veganism to reduce my impact, while expanding my knowledge in plastic recycling.

Let’s Make Some Vegan Food!!!

Upon arrival of a new chef, the opportunity arose for my time to be spent on the new Version 4 Sheet Press system. I moved from the kitchen over to the workspace in order to begin testing the newly created machines.

Let’s Make Some Sheets!!!

First the task.

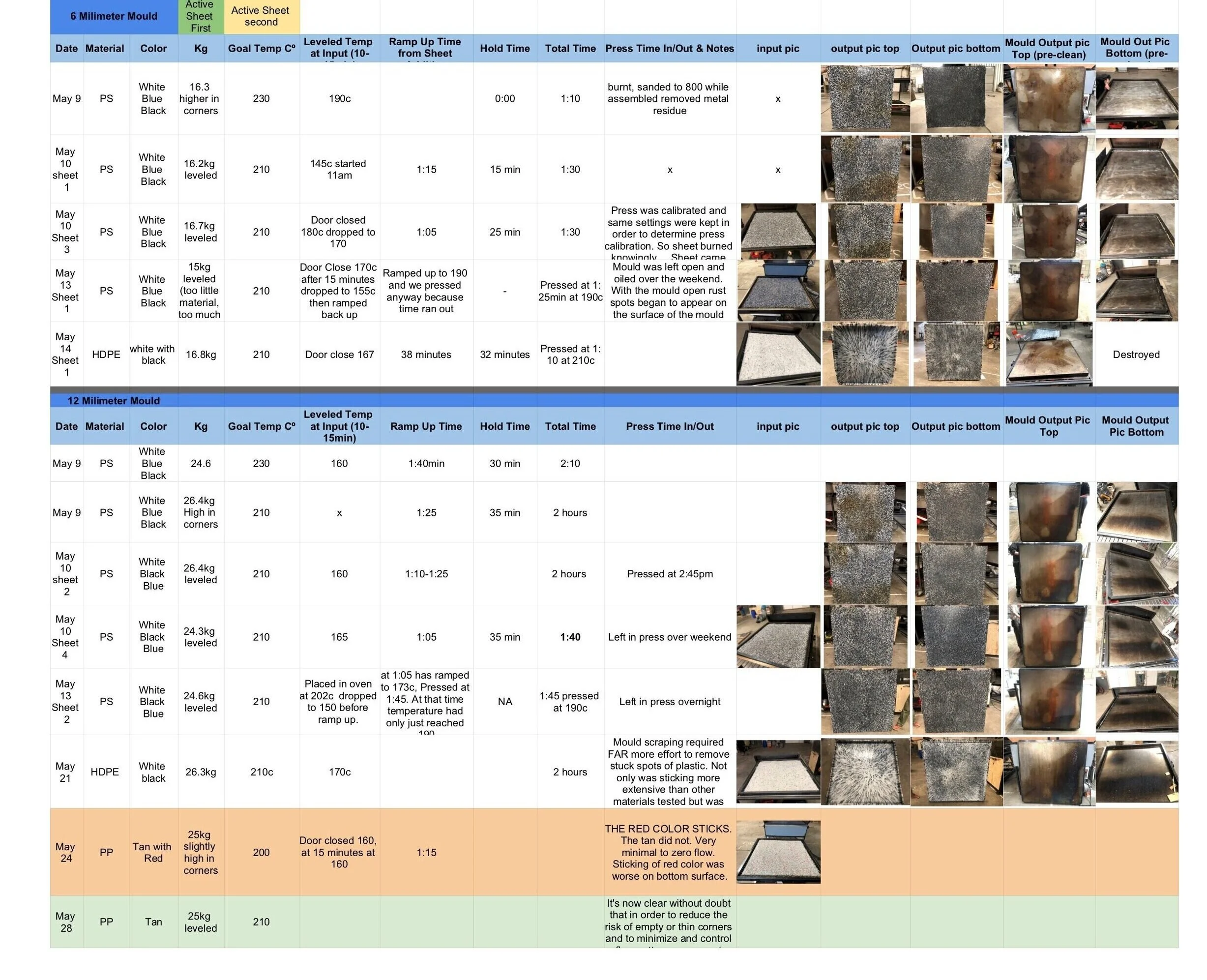

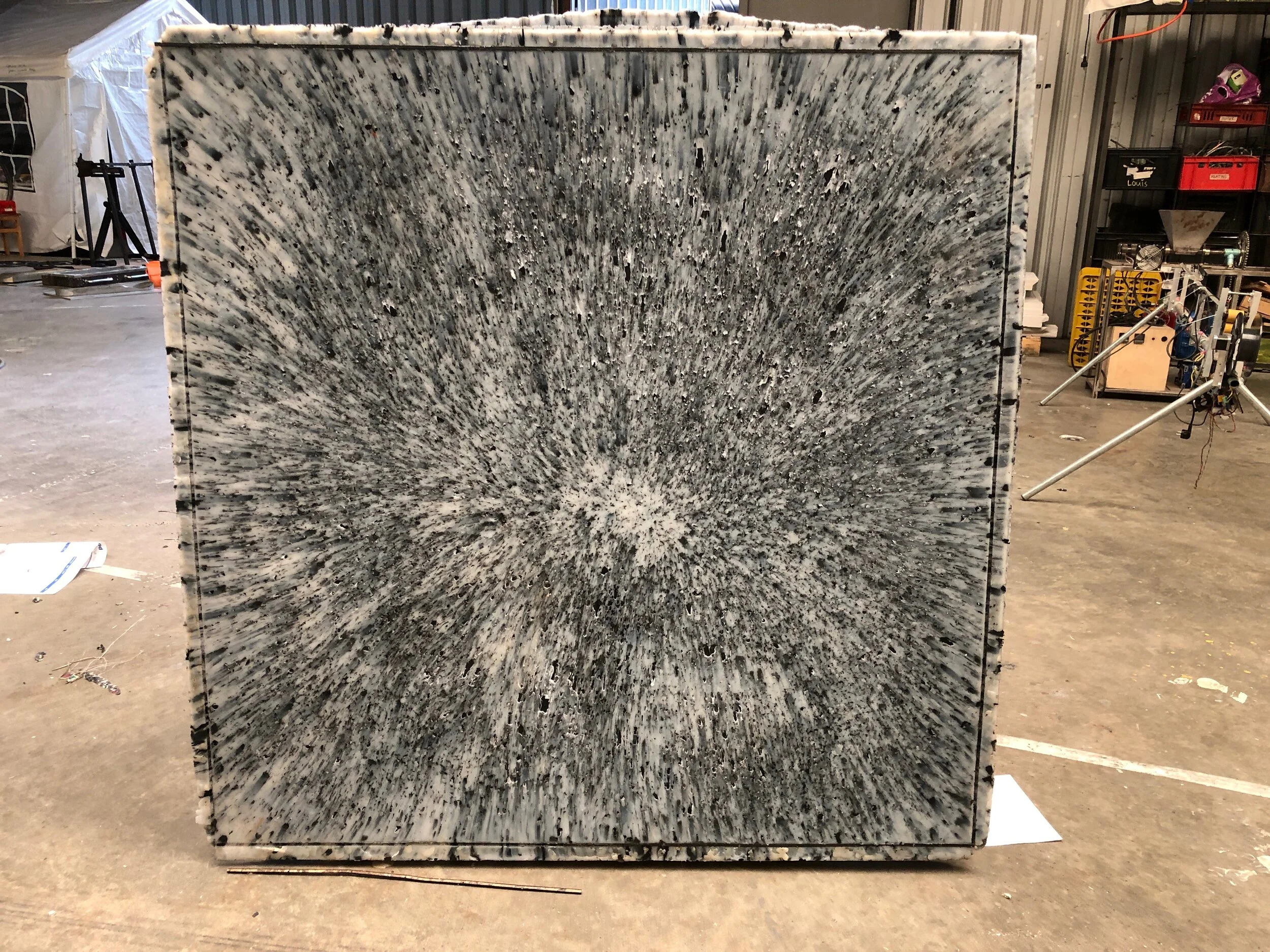

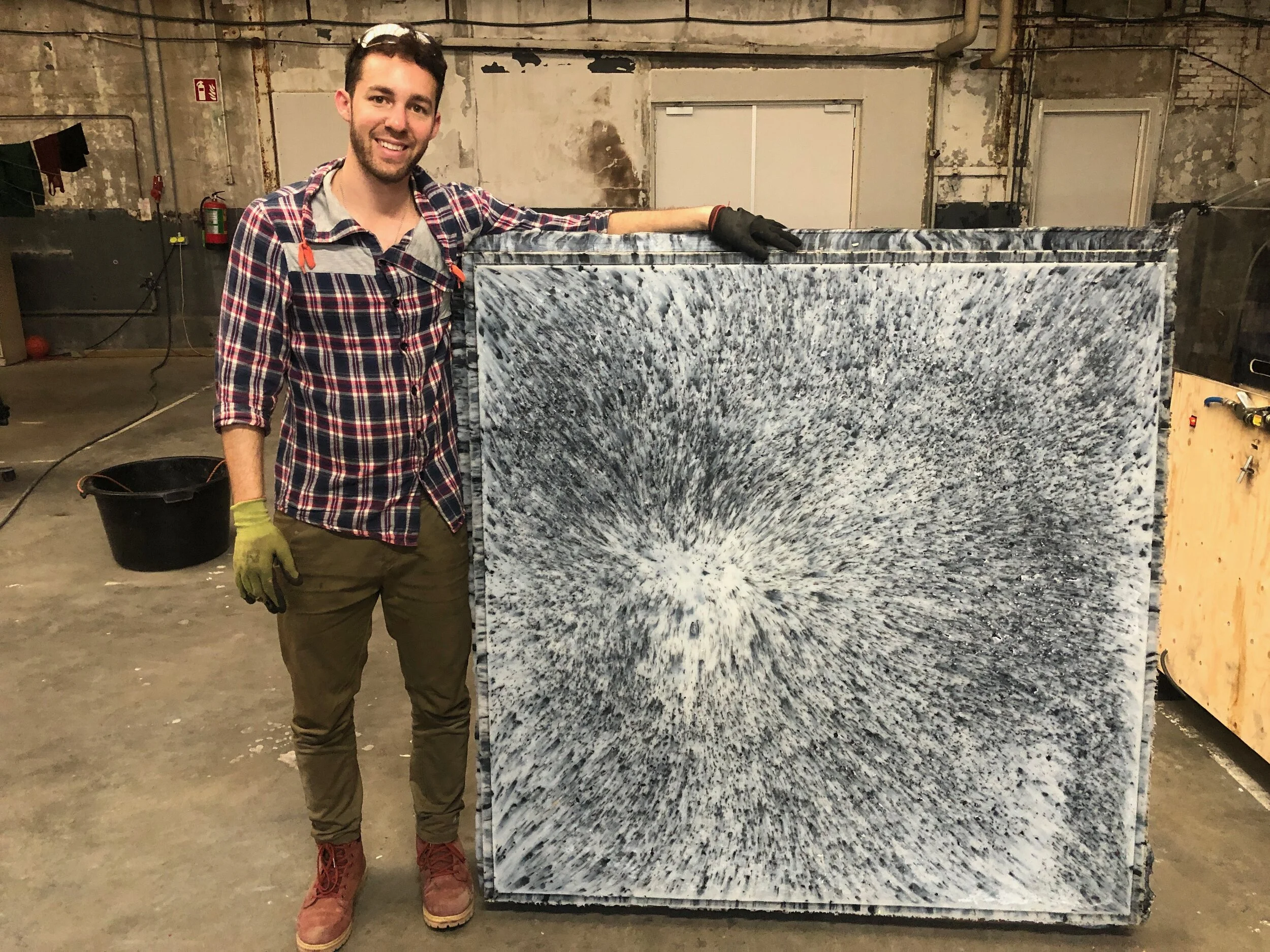

Seen here is a video of Mark and Jason, the engineers of the V4 sheet press system. This is the first sheet ever made on the proof of concept machine. The (simplified) steps involved are to fill the 2 part mold with shredded plastic, load into the oven and bake for a predetermined time and temperature, moving the mold from oven to cold press (seen here) and leave to cool under pressure. Once cooled the sheet is removed and the mold cleaned and prepped again. My task put simply was to begin producing sheets while trouble shooting, providing guidance for future improvements

Before we began the ventilation system needed to be rebuilt and simplified to improve air flow and user safety. We constructed a more direct path with a higher rated fan, and separated the ventilation system from other machines. With the sheet press creating the most fumes of any of the machines, a warning system was put in place and masks were relocated to improve efficiency and access.

Ready to go!

With the ventilation in place, the next steps meant putting in place a testing procedure to begin producing sheets using the new sheet press system concept. All variables were reduced to a minimum and any quantifiable data points were tracked such as temperature changes, timing, and material positioning.

Of course, not everything goes perfectly the first try. Primary issues revolved around sticking, heat distribution, and the bulky maneuvering of heavy and sometimes very hot components. In the end, this feedback and experience lead the team to move towards solution more similar to Version 3’s launch.

Check out the final V4 Sheetpress here!

In the end, my time at Precious Plastic taught me much more than how to recycle plastic. I grew as a designer, a human, and a member of a greater community wherever I may be. I learned of new capabilities I have, built a better appreciation for my history, and grew more confident in my direction and values in life.

Throughout it all was my community. Everyone having such unique backgrounds, histories, and culture, yet so like minded in our pursuits. We learned from each other and shared our knowledge openly. We built a family of sorts, which we can all continue to rely on as we spread across the world again. This type of care and compassion is important and an aspect I plan to make even more prevalent in my future work.